In the three years since its launch GOL Salvage Services Ltd., having forayed into a domain traditionally commanded by global players has today become a force to reckon with. GOL Salvage’s Executive Director,Capt. Sandeep Kalia, gives a rare insight into the Indian salvaging scenario.

‘Fools rush in where angels fear to tread’ had been the deciding factor for most salvors in India, holding them back from entering the salvage business in earnest. But when GOL Salvage Services Ltd. entered the field in 2011, it became a game changer as it was the first fully indigenous salvage company making an entry into the field that was traditionally dominated by overseas salvaging giants.

Not only has it made it big in a short span of time, but it has also added several milestones to its credit including the acquisition of full membership of the International Salvage Union (ISU) in just over a year of existence.

GOL Salvage Services Limited is a wholly owned subsidiary of GOL Offshore Limited (GOL). The GOL Offshore Group, the largest offshore service provider in India, enjoys three decades of continuous diversified experience, a workforce of nearly 1,700, a fleet of 61 multifunctional offshore assets and operations spread worldwide.

The group’s business verticals range from drilling, engineering services, marine and aviation logistics, IMR, ship repairs, port and terminal support to encompass the entire gamut of E&P activities. Having the backing of its global expertise, massive offshore assets and operations spread worldwide, GOL Offshore thus made a remarkable foray into the salvage business in India.

“In most industries investment decisions are based on analysis of the return on capital employed,” said Capt. Sandeep Kalia, Executive Director of GOL Salvage. “Salvaging being a casualty related business does not encourage capital investment based on five-year projections. But high capital intensive investment is imperative. In this respect GOL Salvage has a range of diversified offshore assets owned by the parent company that is made available to it exclusively. These include anchor handlers, tugs, support crafts, cranes and hook up accommodation barges, highly skilled and qualified salvage personnel, offices in both the East and West coasts of India, U.K., Dubai and Malaysia, warehouses, repair facilities, salvage an diving equipment, for example. As a result GOL Salvage is ideally suited for this activity.”

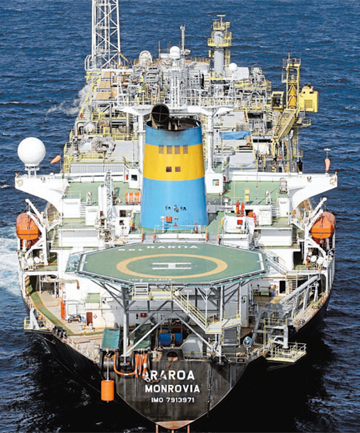

What is remarkable is that the company has within a short period successfully completed several complex and challenging salvage operations. Major jobs include the refloating and delivery of a sunken Indian Naval warship INS Vindhyagiri (as technical partners to Titan Salvage); the refloating of the broadly beached oil tanker MT Pavit from Juhu Beach Mumbai. Another was the high-sea rescue / towing operation of the disabled M. V. Socol 6, carrying Class 1 IMO project cargo, in very rough seas off Marmugao port, in Goa on the Indian west coast. For this operation it mobilized GOL’semergency towing vessel Gal Ross Sea. The company also refloated MT Pratibha Cauvery a tanker stranded at Chennai on the East coast of India, by mobilizing the 120 T bollard pull AHTSV Malaviya Twenty One chartered to another salvor. All these operations according to Capt Kalia achieved a 100% success rate.

GOL Salvage is already a recipient of some coveted awards. For instance, it was conferred with the “Salvage Company of the Year” award at the Samudra Manthan Awards at Mumbai in December 2011. It was also bestowed with Leadership & Excellence Award for “Outstanding Achievement and Innovation in Salvage” during Shipping Marine & Ports Conference February 2012.

“As newcomers we face several challenges,” said Capt Kalia.

“The salvage industry in India is still at a nascent stage. International salvors dominate this niche sector and entry of Indian companies is therefore limited. The economics of this industry has changed over time. Improvements in PSC regimes have reduced the number of casualties. The lack of support or encouragement from the government to promote national companies, outdated Indian laws with respect to salvage and wreck removal and cut-throat competition are still deterrents for prospective players envisaging to enter this business.”

Describing the prevailing unfavorable laws and regulations, he points out that the Indian laws with respect to wreck removal are laid down in Part XIII of the Merchant Shipping Act, 1958 and in the Indian Ports Act, 1908. These make shipowners legally liable to remove wrecks from the territorial waters only, and then too only if they pose a hazard in the shipping lanes or lie close to a navigation channel.

Hence, he affirms shipowners, managers and underwriters abandon their property as the provisions of our law do not bind them to get rid of the nuisance, posing a hazard not only to marine life but to the earth’s ecosystem as well. He draws attention to the fact that Indian salvage operators are at a disadvantage compared to many maritime countries. As in the U.S., where the Jones Act is in force, there is not much encouragement or reforms brought into place by the government of India to promote or support Indian players. “A lack of recognition of national competence is purely driven by ignorance and this has to change,” he said. “There is an imperative need to reform our cabotage law and to promote capacity building as there is enough talent and capacity in the country to be self sufficient.”

Capt. Kalia looks forward to the International Maritime Organization’s (IMO) Nairobi Wreck Removal Convention of 2007 coming into force as this he contends will empower states to order the removal of wrecks from the waters that extend from their territorial waters to the 200-mile exclusive economic zone (EEZ). He explains that instances of owners and underwriters abandoning their ships’ wrecks outside Indian territorial waters, for example, M/V Rak Carrier, M/T Pavit and many more, will witness a sharp decline, providing a relief to the country’s coastal states and generate business opportunities for salvors.

Capt. Kalia rightly points out that while unpredictable, there will always be a need for salvage, as no matter how sophisticated the technology and the build, human mistakes – as well as technical failure – invariably happen, particularly in the demanding marine environment.

“More than 400 shipping casualties occur globally each year,” said Capt Kalia. “The complexity and cost of these operations are increasing. Though there are around 60 members currently enrolled with International Salvage Union, there is enough business for established players and newcomers. Financial strength, endurance, diversification and appetite for risk are some of the governing factors.”

GOL Salvage is unique in that all of its assets are registered under Indian Flag, many of which are operating in Indian waters, helping to effectively reduce delays and costs. Capt Kalia said that since their offices, warehouses and assets were strategically located on both the east and west coasts of India, it is naturally in a better position to provide a quick response and cost effective quality service to clients without any delays arising due to logistics, mobilization of assets, equipment and clearances from various Indian authorities.

In addition to marine salvage, wreck removal services and protection of marine environment, GOL Salvage also offers a raft of other services, including lightering services, marine firefighting, shallow and deep water towing and anchor handling, search and rescue services, oil spill consultancy, barge and heavy crane lift operations, air and saturation diving and other emergency marine response.

“Using our unique in house, custom built world class DNV-approved offshore ship/anchor handling, towing and crane handling simulator, we are able to simulate complex operations, carry out deployment in various weather / sea conditions / night / day operations and build the team’s experience ashore as well as at sea,” said Capt Kalia. “Our simulators are integrated for complete salvage, OSR training, including creation of a variety of scenarios; provide team training across divergent groups between bridge, engineering and crane teams. The presence of our group in the industry for three decades has not only enriched our combined experience and expertise, but has also benefitted our team’s understanding of local topographical conditions vide our extensive operations. No other national or international agency can claim to posses this edge.”

Speaking about the transformation taking place in the business, he said that salvaging has undergone a kind of metamorphosis. The scenario is quite different today from what it was in the early 80s. Environmental concerns are more significant today and play a far greater part in operations. For instance the bunker fuel capacity of modern day shipping is massive, with bulkers, box ships, tankers and cruise liners having fuel carrying capacities well in excess of 5,000 tons.

On another front the protection of the marine environment has gained dominance while undertaking salvage operations. The mission is to “keep the pollutants in the ship”. The next generation container ships with 18,000 TEU capacity present equally big challenges to the salvage community. With the shipping industry experiencing the worst recession ever, how the industry matches the demands of heavy capital investment to cater to the ever growing tonnage will determine how prolific the salvage business will be in the next generation.

(As published in the October 2013 edition of Maritime Reporter & Engineering News –www.marinelink.com)